During its existence, our Company has manufactured and built steel structures for the aviation, energy, water engineering and automotive industries.

Other steel structures

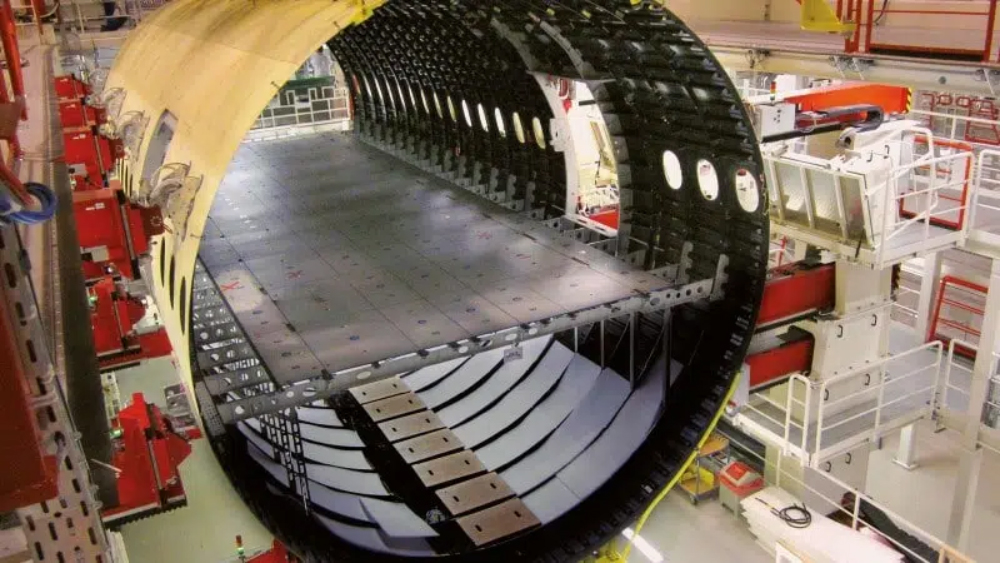

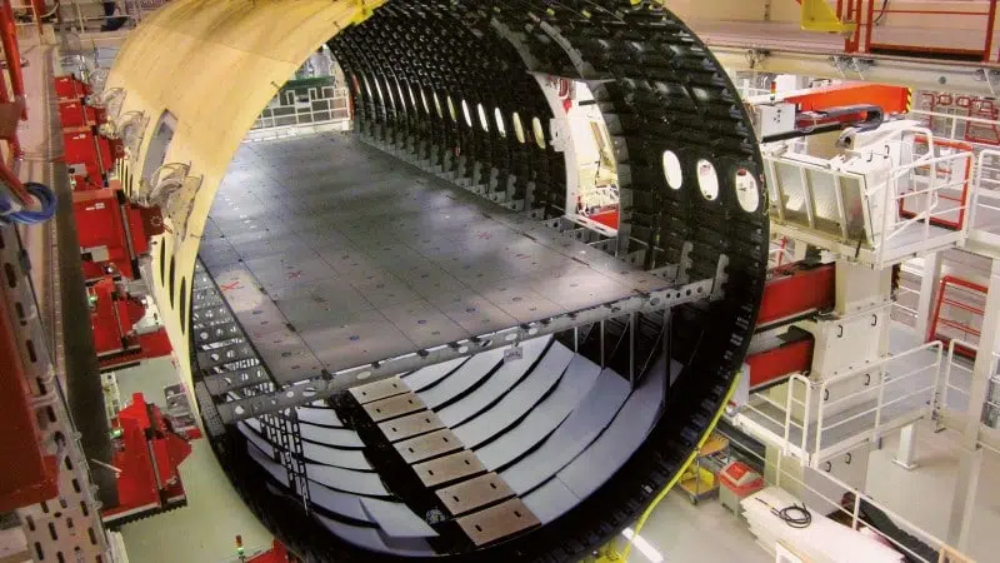

For the aviation industry, MCE is designing, developing and implementing customized solutions in the field of demanding steel structures. Over the years, our Company has gained considerable experience in the production and construction of assembly lines and transport equipment.

References

Thanks to its many years of experience and know-how in mechanical engineering, steel structures and control technology, MCE has been building wind tunnels as a main contractor for more than two decades. The focus of the climate wind tunnels is the testing of vehicles in all possible weather and climate conditions, with a high level of repeatability. Whether it is rain, snow, dry or wet weather, or sunshine, even -40 or +60 degrees Celsius, the most unusual options should be made possible.

ReferencesOur Company has been the audited supplier of gas turbine foundations and other machine foundations of a global energy company for nearly 2 decades. Our Company has produced gas turbine foundations for our Customer, for all parts of the world.

References

The gate structures of the dams and reservoirs required for the operation of hydropower plants are demanding steel structures, and their construction is a serious professional challenge – also due to their sizes and technological requirements. During the construction of several hydropower plants, our Company has produced demanding steel structures and sluice gates.

References